PARTNERSHIPS

Inside the Sumitomo-Toshiba Push for Automated Leak Detection

A new partnership marks a step toward automated, non-contact leak detection, starting in semiconductor plants and expanding to other industries

11 Nov 2025

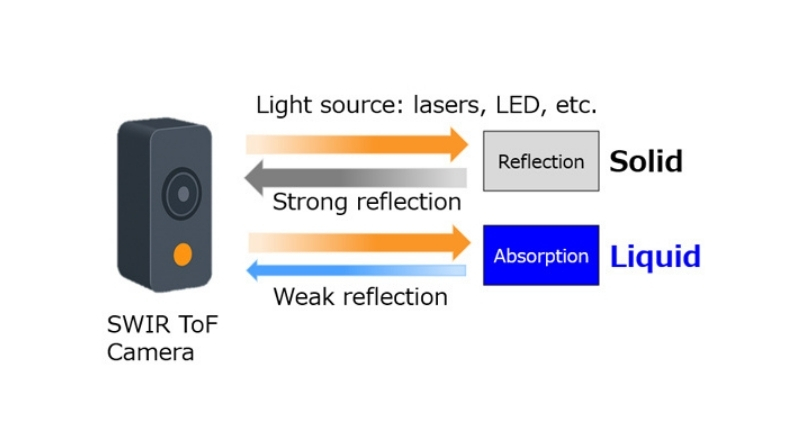

Sumitomo Corporation and Toshiba Information Systems have formed a partnership to develop automated, non-contact leak detection technology, signalling a shift away from manual inspections toward continuous monitoring across industrial sites.

The collaboration centres on a system that scans wide areas without attaching sensors to individual pipes, tanks or machines. Instead, it observes facilities remotely and alerts operators when anomalies are detected. Sumitomo said sales are expected to begin after August 2026, following completion of the patent application process scheduled for September 2025.

Leaks remain a common and costly problem for industrial operators, disrupting production, creating safety risks and exposing companies to environmental or regulatory penalties. Traditional detection methods, which often rely on periodic manual checks or asset-by-asset sensors, can miss early warning signs and require regular maintenance. These shortcomings are becoming more apparent as industrial facilities grow larger and more complex.

The initial focus for the new system will be semiconductor manufacturing plants, where equipment uptime and process stability are critical. Sumitomo brings experience in deploying industrial solutions at scale, while Toshiba Information Systems contributes software and data analysis capabilities that enable automated identification of leaks involving water, chemicals or oil.

The partners plan to extend the technology into other sectors, including chemicals and pharmaceuticals, where leak prevention is closely linked to safety and compliance. Industry analysts say the timing reflects rising pressure on manufacturers to reduce downtime, improve safety records and limit waste, particularly in high-value production environments.

Automated monitoring could lower costs by reducing the need for physical sensors and by allowing maintenance teams to focus on confirmed risks rather than routine inspections. In regulated industries, faster detection may also help companies limit the impact of incidents and meet reporting requirements more effectively.

However, challenges remain. The system will need to demonstrate reliability in varied operating conditions and integrate with existing maintenance and data systems. Companies adopting the technology will also have to manage larger volumes of monitoring data as digital tools play a bigger role in operations.

Even so, the partnership reflects a broader trend in industrial maintenance, as automation moves from pilot projects into core infrastructure. For many operators, early leak detection is increasingly seen less as an optional upgrade and more as a requirement for safe and efficient operations.

Latest News

13 Feb 2026

AI Sniffs out Leaks Beneath Europe’s Streets10 Feb 2026

Europe Turns to Satellites in the Fight Against Water Leaks4 Feb 2026

Digital Fixes for Europe’s Dripping Infrastructure6 Dec 2025

Listening Without Pause: The Tech Behind Europe’s Leak Fight

Related News

RESEARCH

13 Feb 2026

AI Sniffs out Leaks Beneath Europe’s Streets

PARTNERSHIPS

10 Feb 2026

Europe Turns to Satellites in the Fight Against Water Leaks

TECHNOLOGY

4 Feb 2026

Digital Fixes for Europe’s Dripping Infrastructure

SUBSCRIBE FOR UPDATES

By submitting, you agree to receive email communications from the event organizers, including upcoming promotions and discounted tickets, news, and access to related events.